Precautions When Processing Plexiglass Engraving

Jun 28, 2021

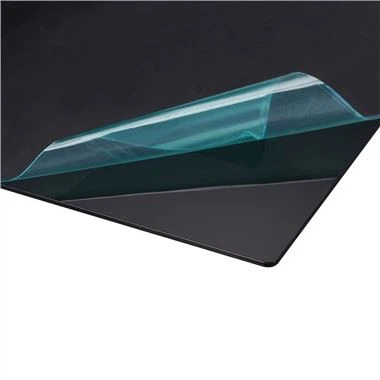

Plexiglass processing has become a common demand in people's daily life, and it is widely used in all walks of life. Plexiglass customization often involves production processes such as engraving, silk screen printing, bonding, and hot bending.

1. First, make sure that the plate is of high purity when making plexiglass processing customization, otherwise the purchased material may melt during engraving or cutting. The commonly used engraving materials, second only to wood, are relatively low-cost, convenient and practical, and can be carved into various shapes that customers want.

2. Choose a three-dimensional carving plan as much as possible for the carving settings, and choose a 90-degree tapered knife for carving, so that the roughness on the carving surface can be visually reduced, and a good foundation for subsequent customization is laid.

3. Do not have layered engraving during engraving setting, and set the appropriate depth at one time. Otherwise, overlap marks will appear after layered engraving, which will affect the smoothness of the spray paint and silk screen of the engraved part.