What is Perspex Sheet

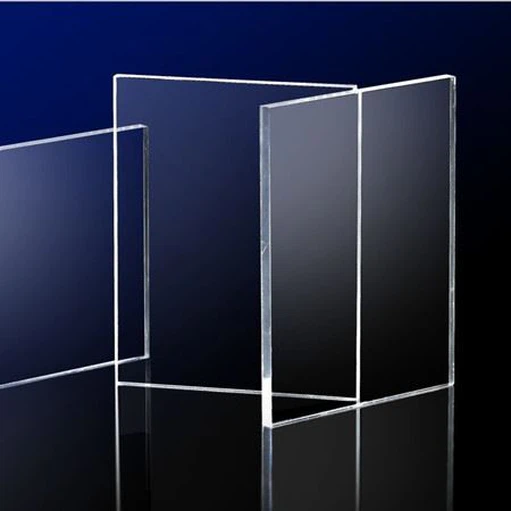

Perspex sheet is a versatile and widely used material in various industries, known for its exceptional clarity, durability, and flexibility. In this comprehensive guide, we will delve deep into the world of perspex sheets, exploring their properties, manufacturing processes, applications, and more. Whether you're a professional in the field or simply curious about this remarkable material, this article will provide you with a comprehensive understanding of perspex sheets.Perspex sheets, also known as acrylic sheets, plexiglass, or acrylic glass, are transparent thermoplastic panels renowned for their optical clarity and versatility. They have gained popularity in various industries, including construction, automotive, aerospace, and art, due to their unique combination of properties.

why choose us

Experience

We have years of experience producing high-quality acrylic sheets for businesses around the world.

Expertise

We have a team of experienced professionals who ensure that all our products meet superior quality standards.

State-of-the-art technology

Our state-of-the-art technology ensures that all our products are of the highest quality, providing reliability and durability for years to come.

Competitive Prices

We offer competitive prices that are affordable for businesses of all sizes.

-

Perspex sheets perfects for DIY, art projects, laser engraved display, signage nameplate, photo

Add to Inquiry -

Density: 1.2g/cm3. Color: Clear, transparent, marble, frosted, mirror, red, blue, white, black,

Add to Inquiry

Benefits of Perspex Sheet

A Wide Variety of Colours

Perspex Sheets are available in a huge range of colours and finishes. There are hundreds of colours that can be made custom for various projects. Also, finishes such as Gloss, Frosted, Tints and Glitters are available. This gives people the opportunity to create a wide range of products and let their imagination run wild. Combining different colours and finishes creates wonderful effects. This wide range of colours is useful for matching or creating branding. Whether it be a small business or a worldwide name, the perfect tone can be found.

Easy to Clean

Acrylic sheets and products are fairly easy to clean, with the right products. One of the best ways to clean your acrylic is to use soapy water with a micro-fibre cloth. Using washing up detergent will create a soapy lather, whilst the micro-fibre cloth will deal with any dirt that is sitting on the panel. Also, if possible, handling the edges of the panel rather than the face. This also prevents scratching and any fingerprints on the face.

Reusable

As it is a synthetic material, acrylic can be reused as products. Such as laser cut jewellery, signage, homeware and more. Any offcuts can also be sold online to reuse waste material. Providing online craft sellers with materials for projects and products. This the most eco-friendly solution for spare sheets. Perspex have stated that they never send any acrylic material to a land fill.

Pliable

Perspex sheets can be heated and formed due to its elastic nature. It is flexible and can be easily moulded into any shape. This is perfect for projects such as lighting, furniture, screens, decorative items and more. There are a variety of techniques that can be used to work with the material and get it to the shape required. Techniques include Dome Blowing, Line Bending and Drape Forming to name a few.

What are the Applications of Perspex Sheet

Signage

Perspex sheets are often used for outdoor and indoor signage. They can be easily cut into various shapes and sizes and are durable enough to withstand different weather conditions.

Display Cases

Perspex is commonly used to create display cases for museums, retail stores, and exhibitions. It offers excellent clarity and UV resistance, protecting valuable items from dust and damage.

Lighting

Perspex sheets are used in the lighting industry for diffusers and light fixtures. They can be laser-cut to create intricate designs that enhance the aesthetic appeal of lighting installations.

Furniture

Acrylic furniture, such as chairs, tables, and shelves, is trendy due to its modern and sleek appearance. Perspex sheets are also used to make protective covers for furniture.

Architectural Glazing

In architecture, acrylic sheets can be used as windows, skylights, and canopies. They provide natural light while being more lightweight than glass.

Aquariums

Large acrylic sheets are commonly used to construct aquariums. They offer excellent clarity and are less prone to shattering than glass.

Medical Equipment

Acrylic is used for medical equipment like isolation boxes, splash guards, and protective barriers due to its transparency, ease of cleaning, and durability.

Automotive

In the automotive industry, Perspex sheets are used for windows in certain vehicle models, especially in racing cars and boats, due to their lightweight properties.

Perspex Sheet Features

Transparency

Perspex sheet has excellent optical clarity, similar to glass, allowing it to transmit up to 92% of visible light, which makes it ideal for uses where visibility is important, such as in advertising displays or aquariums.

Light Weight

Perspex sheet is significantly lighter than glass, weighing approximately half as much, which eases transportation, installation, and reduces the load on supporting structures.

Impact Resistance

Perspex sheet is much more resistant to impact than glass, making it less likely to break and safer to use in environments where there is a risk of accidental collisions or flying debris, such as in playground equipment or shop fronts.

Thermoplastic Properties

Being a thermoplastic, Perspex sheet can be heated and molded into various shapes, allowing for versatility in design and manufacturing. It can be cut, drilled, and formed easily using standard woodworking and metalworking tools.

Chemical Resistance

Perspex sheet is resistant to many common chemicals, including alkalis and some acids, which means it can be used in laboratory settings or in environments where it might come into contact with cleaning agents or solvents.

Weather Resistance

Perspex sheet is stable against UV radiation and does not yellow easily, which makes it suitable for outdoor use, such as in signs or glazing for greenhouses.

Manufacturing Process of Perspex Sheet

Extrusion

One of the common methods for manufacturing perspex sheets is extrusion. In this process, polymethyl methacrylate (PMMA) pellets are heated and forced through a die to create a continuous sheet. This method is cost-effective and suitable for producing sheets of consistent thickness.

Cell Casting

Cell casting, or bulk polymerization, involves pouring liquid acrylic between two sheets of glass and allowing it to cure. This method yields sheets with exceptional optical clarity but can be more labor-intensive and costly.

Injection Molding

Injection molding is used to create complex shapes and designs from acrylic. It involves injecting melted acrylic into a mold and allowing it to cool and solidify. This process is often employed for manufacturing intricate acrylic products.

Types of Perspex Sheet

Clear Perspex: This is the standard, clear acrylic sheet that most people associate with Perspex. It offers excellent optical clarity and is commonly used for windows, protective screens, displays, and signage.

Colored Perspex: Acrylic sheets can be tinted or colored during the manufacturing process to achieve a wide range of colors. Colored Perspex sheets are used for decorative purposes, signage, and artistic projects.

Opal Perspex: Opal or opaque Perspex sheets are translucent but not transparent. They diffuse light, making them ideal for lightboxes, signs, and architectural applications where a soft, even illumination is desired.

Mirror Perspex: Mirror acrylic sheets have a reflective surface similar to a traditional glass mirror but are much lighter and more durable. They are used in interior design, retail displays, and decorative applications.

Frosted Perspex: Frosted acrylic sheets have a matte, textured surface that diffuses light and provides privacy. They are often used for partitions, shower screens, and decorative elements.

UV-Resistant Perspex: Some acrylic sheets are treated to be UV-resistant, which makes them suitable for outdoor applications. They can withstand prolonged exposure to sunlight without yellowing or becoming brittle.

Fluorescent Perspex: These acrylic sheets are infused with fluorescent pigments, making them glow under UV or blacklight. They are popular for signage, artwork, and decorative installations.

Anti-Glare Perspex: Anti-glare acrylic sheets are designed to reduce reflections and glare, making them suitable for picture framing, museum displays, and electronic device screens.

Impact-Resistant Perspex: This type of acrylic sheet is engineered to be more impact-resistant than standard acrylic. It is used in applications where increased durability and resistance to breakage are essential.

Fire-Retardant Perspex: Fire-retardant acrylic sheets are formulated to meet fire safety regulations. They are used in buildings and areas where fire safety is a concern.

How to Choose Perspex Sheet

Thickness

Perspex sheets come in various thicknesses, ranging from thin films to thick slabs. Select the appropriate thickness based on the application's structural requirements and weight considerations.

Size

Measure the area where the Perspex sheet will be installed to ensure it fits properly. Custom sizes can often be ordered if standard sizes do not suit your needs.

Color and Transparency

Determine whether you need clear, colored, or frosted Perspex. Clear Perspex is most common for its transparency, but colored or frosted options can be chosen for aesthetic or privacy purposes.

Hardness

Perspex sheets are available in different hardness levels. Higher hardness is generally more resistant to scratches and impacts but can be more difficult to work with during fabrication.

Fire Rating

If the Perspex sheet will be used in an environment with strict fire regulations, select a grade that meets the required fire resistance standards.

UV Resistance

For outdoor use or areas exposed to sunlight, choose a UV-resistant Perspex to prevent yellowing and degradation over time.

How to Maintain Perspex Sheet

Prevent high temperature

The temperature of the perspex sheet should not exceed 90 degrees during continuous use.Because the thermal deformation of the general perspex sheet is stable at about 100 degrees,The temperature of the general perspex sheelt at 98 ℃ will cause thermal deformation, so high temperature deformation of acrylic products should be prevented.

Avoid touching with sharp objects

The perspex sheet is actually a kind of organic plastic. Although the general hardness can meet many application scenarios, if there is a special purpose, then we can harden the perspex shee to prevent scratches, so that its hardness can reach 3H.If the perspex shee encounters harder things such as nails and other pins, at this moment we can increase the hardness of the perspex sheelt to 6H,

Soft towel + 1% soapy water for decontamination

If the perspex sheet is blurred or unclean due to slight scratches or dust adsorption caused by static electricity,Or there will be a layer of gray on the perspex shee for other reasons.We recommend cleaning with 1% soapy water and a soft cloth.Scrubbing in this way is not only clean, but also not easy to stain the dust layer again. And it does not need to be rinsed with clean water again, which is convenient to clean and is not easy to leave hand marks on the perspex shee.

Pay attention to thermal expansion and cold contraction

When maintaining the perspex sheet, you will generally encounter characteristics. The length, width and height of the perspex sheelt will increase, but it will decrease in winter.This is because the perspex sheelt has a certain expansion coefficient, so the factory should consider the thermal expansion and cold contraction coefficient of the acrylic panel during the installation process,And take into account the stretching gap during assembly. This is the detail that must be paid attention to in the process of assembling the perspex sheelt.roduct.

Properties of Perspex Sheets

Transparency: Perspex sheets are renowned for their exceptional optical clarity, allowing them to transmit up to 92% of visible light. This property makes them an excellent substitute for traditional glass in applications where transparency is crucial.

Durability: Despite being lightweight, perspex sheets are incredibly durable and impact-resistant. They can withstand significant physical stress without shattering, which enhances safety in various settings.

Weather Resistance: Perspex sheets exhibit outstanding resistance to environmental factors such as UV radiation and weathering. They can maintain their clarity and structural integrity when exposed to the elements, making them suitable for outdoor applications.

Lightweight: One of the advantages of perspex sheets is their low density. They are significantly lighter than glass, making them easier to handle, transport, and install, which can be particularly beneficial in construction and transportation industries.

Chemical Resistance: Perspex sheets are resistant to many chemicals, making them suitable for use in laboratories, chemical processing facilities, and other environments where exposure to corrosive substances is a concern. This property ensures their longevity and reliability.

Thermal Insulation: While not as effective as some other materials, perspex sheets provide a degree of thermal insulation. They can help reduce heat transfer, which can be advantageous in applications requiring temperature control, such as greenhouses.

Electrical Insulation: Perspex sheets are electrically insulating, making them suitable for use in electrical and electronic equipment where avoiding electrical conductivity is essential for safety and functionality.

Customizability: These sheets can be easily cut, shaped, and fabricated to meet specific requirements. This customizability allows for the creation of intricate designs and tailored solutions in various industries, including art and signage.

Sound Transmission: Perspex sheets can transmit sound, making them useful in applications like acoustic barriers. They can be designed to absorb or reflect sound waves, contributing to noise reduction.

Variety of Types: There are different types of perspex sheets available, including clear, colored, textured, UV-resistant, and frosted varieties. Each type has its unique set of properties and is suited to specific applications.

Our Factory

With several 1000000 square meters factories, we can easily reach large demanding request from our clients, our never ending research and development has lead to tremendous quality increase in our products. We also offer free sample service, whatever you need, just tell us the required data and we’ll make your illusory concept in mind from sketches or CAD blueprints to real product as soon as possible.

FAQ

Q: What is the difference between Perspex and acrylic sheets?

Q: Can Perspex sheets be used outdoors?

Q: Are Perspex sheets as strong as glass?

Q: How do I clean and maintain Perspex sheets?

Q: Is acrylic sheet the same as Perspex?

Q: What are Perspex sheets used for?

Q: What is a cheap alternative to Perspex?

Q: Does Perspex crack easily?

Q: How long does Perspex last?

Q: Is Perspex cheaper than glass?

Q: Is Perspex a glass or plastic?

Q: Which is better acrylic or Perspex?

Q: Is 2mm Perspex strong?

Q: Is 5mm Perspex strong?

Q: Can you use Perspex in a shower?

Q: Can I replace glass with perspex?

Q: Why replace glass with perspex?

Q: How do you cut perspex?

Q: Does Perspex discolour?

Q: Is Perspex fireproof?

As one of the most professional perspex sheet manufacturers and suppliers in China, we're featured by quality products and good service. Please rest assured to wholesale bulk high-grade perspex sheet made in China here from our factory.

Perspex Glass Sheet, perspex glass for sale, large perspex sheets